- Home

- CNC Machining

CNC Machining

Fast Turnaround High Precision CNC Turning and Milling

CNC Turning & Milling

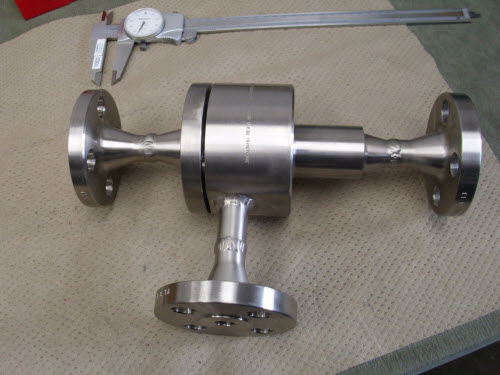

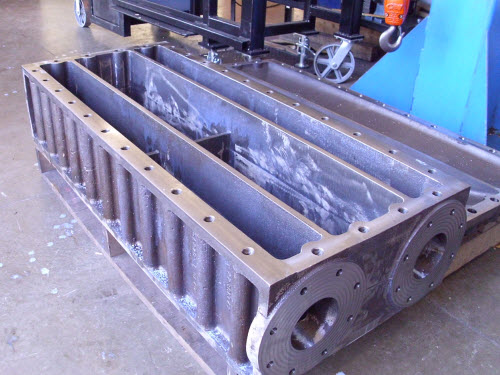

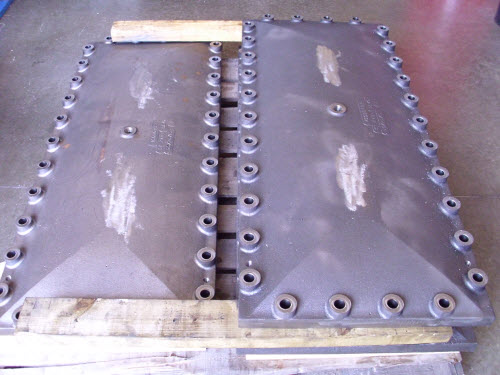

Rem-Tech Industries offers custom CNC machining services for sleeves, shafts, pump rings, metal seal faces, compression units, food processing equipment parts, and other components.

We specialize in quick turnaround CNC and manual turning and milling of super alloys and hard to machine materials including Stainless Steel alloys, Super Duplex, Titanium, Inconel and Hastelloy.

Rem-Tech relies on an optimal work flow to provide fast response times. Eight-hour turnaround for low volume machining of components is normal at our facility.

Click here for machine capabilitiesCNC Machined Parts

Machining Capabilities

| Machine Type | Qty | Description | Max Capacity | Max Capacity (L) | Max |

|---|---|---|---|---|---|

| Lathe - CNC | 6 | Lathe With Milling Package | Up to 34" ⌀ | 120" | 6" ⌀ Thru Spindle |

| Lathe - CNC High Production | 2 | Double Chucker With Milling Package | 10" | 40" | 3.15 Thru Spindle |

| Lathe - CNC | 17 | Regular | 18" | 60" | 4" ⌀ Thru Spindle |

| Lathes - Manual | 5 | 2-Axis | 26" ⌀ | 80" | 4" ⌀ Thru Spindle |

| Milling Machines - CNC | 5 | 5-Axis | Up to 35" ⌀ | ||

| Milling Machines - CNC | 1 | 3-Axis Large Table | X-Axis 84" | Y-Axis 47" | Z-Axis 36" |

| Milling Machines - CNC | 9 | 3-Axis and 4-Axis | Up to X-Axis 40" | Up to Y-Axis 20" | Z-Axis 30" |

| Milling Machines - Manual | 3 | Bridgeport Style | X Axis 52" | Y Axis 16" | |

| Saws | 5 | Band Saw | Up to 22" ⌀ | - | - |

| Grinders - Surface | 1 | Surface Grinder | X-Axis 12" | Y-Axis 24" | - |

| Grinders - Precision | 2 | Vertical Spindle | 12" ⌀ | 6" | |

| Grinders - OD/ID | 6 | OD/ID Grinder | ⌀ 24"OD/30"ID | 120" | - |

| Lapping | 2 | Face Lapping | 10" ⌀ | ||

| EDM | 1 | Wire EDM | 32 X 32" ⌀ | 15" | |

| Thermal Spray | 1 | F-4 Plasma Gun | 30" ⌀ | 60" | |

| 1 | JP-5000 HVOF Gun (Kerosene) | 30" ⌀ | 60" | ||

| 1 | WOKAJET HVOF Gun (Kerosene) | 40"-60" ⌀ | up to 144" | ||

| 1 | SG-100 Plasma Gun | 30" ⌀ | 60" | ||

| 1 | ID Plasma Gun | (min) 3" ⌀ ID | 32" | ||

| 1 | Thermal Spray Camera AccuraSpray 4.0 With universal sensor head | Substrate Pyrometer | |||

| Static Leak Testing | 1 | Test Bench | Up to 5000 psi. | ||

| PMI (XRF) Non-Destructive Material Testing | 1 | Niton XRF gun (X-Ray Fluorescence Analysis) - used to evaluate/validate chemical composition of parts or materials | |||

| Metrology | 1 | WENZEL & MITUTOYO CMMs | Capacity 60"W X 40"L X 30"H | ||

| 3 | Surface Roughness Tester | Ra, Rz, Rmax | |||

| 2 | MAHR RCF (Profile) Gauge | Dynamic Roundness, Concentricity, Flatness measurement | |||

| 1 | MITUTOYO Hardness Tester | Various Hardness Scales | |||

| 1 | Portable Hardness Tester | Various Hardness Scales | |||

| 2 | Universal pre-setting gauge | 19.68" Length | |||

| Special Processes through strategic partnerships | Heat Treating | ||||

| Plating/Coatings - NCB, Oxide Finishes | |||||

| Laser Cutting | |||||

| Welding and fabricating Steel and Stainless steel | |||||

Find Out Why Rem-Tech is The Preferred Machining Partner of Industry Leaders

Talk to our experts today.